Product Description

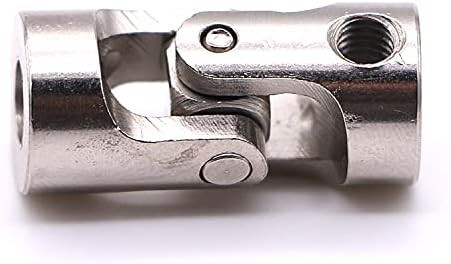

high quality Hardy Spicer Cardan Constant-velocity propshaft steering shaft removing pto coupling double front rear best universal joint

Application of universal joint

Universal joints, also known as U-joints, are mechanical joints that allow 2 shafts to rotate at different angles. They are commonly used in driveshafts to transmit power from the engine to the wheels of a vehicle. U-joints are also used in other applications, such as:

- Wind turbines: U-joints are used in wind turbines to transmit power from the blades to the generator.

- Robotics: U-joints are used in robotics to move the robot’s arms and joints.

- Aircraft: U-joints are used in aircraft to transmit power from the engine to the propeller.

- Machine tools: U-joints are used in machine tools to transmit power from the motor to the cutting tool.

- Conveyors: U-joints are used in conveyors to transmit power from the motor to the conveyor belt.

U-joints are a versatile and reliable component that can be used in a wide variety of applications. They are characterized by their ability to transmit power through a wide range of angles, and their ability to withstand high torque and vibration.

Here are some of the advantages of using universal joints:

- Ability to transmit power through a wide range of angles: U-joints can transmit power through a wide range of angles, which makes them ideal for applications where the shafts are not aligned.

- Ability to withstand high torque and vibration: U-joints are designed to withstand high torque and vibration, which makes them ideal for applications where these forces are present.

- Versatility: U-joints can be used in a wide variety of applications, which makes them a versatile component.

- Reliability: U-joints are designed to be reliable and to last for a long time.

Overall, universal joints are a versatile and reliable component that can be used in a wide variety of applications. They are characterized by their ability to transmit power through a wide range of angles, their ability to withstand high torque and vibration, their versatility, and their reliability.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Impact of Size and Design on Cardan Coupling Performance and Durability

The size and design of a cardan coupling play a crucial role in determining its performance and durability across various applications:

- Load Capacity: Larger and more robust cardan couplings are generally designed to handle higher torque and load capacities, making them suitable for heavy-duty applications.

- Flexibility: The design of the coupling’s universal joint and its flexibility affect how well it can accommodate angular misalignment while maintaining smooth power transmission.

- Alignment Tolerance: Well-designed cardan couplings have better alignment tolerances, allowing them to operate efficiently even in conditions with slight misalignment.

- Materials: The choice of materials impacts the coupling’s strength, corrosion resistance, and overall durability, especially in harsh environments.

- Bearing Arrangement: The bearing arrangement within the coupling affects its ability to withstand both axial and radial forces, which is crucial for stability.

- Sealing: Effective sealing mechanisms prevent contaminants from entering the coupling, ensuring smooth operation and preventing premature wear.

- Dynamic Balance: Proper dynamic balance reduces vibrations and stress on connected components, contributing to extended coupling life.

- Lubrication: The design should allow for adequate lubrication, which is essential for reducing friction and wear.

- Installation and Maintenance: A well-designed coupling should be easy to install and maintain, with accessible lubrication points and inspection areas.

Ultimately, the size and design of a cardan coupling should be carefully matched to the specific requirements of the application to ensure optimal performance, reliability, and longevity.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-05-09